Petit pain de toiture en acier métallique formant la machine de haute qualité

Informations de base

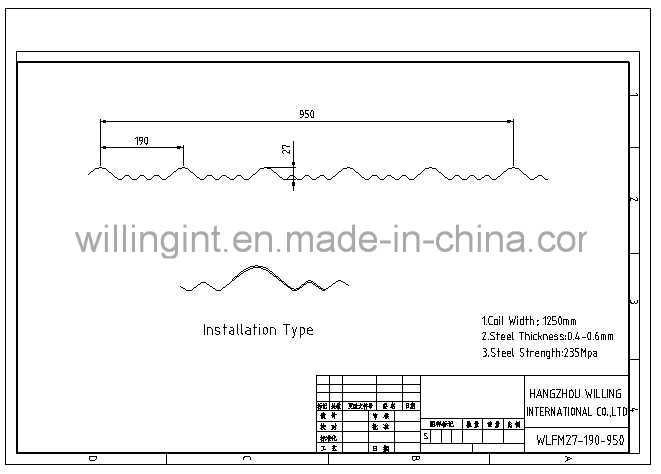

Modèle: WLYX27-190-950

Description du produit

N ° de modèle: WLYX27-190-950 Condition: Nouveau Personnalisé: Personnalisé Source d'alimentation: Électrique Type de produit: Rouleau formant la machine Largeur de la bobine: 1200 Puissance du moteur principal: 5.5kw Diamètre de l'arbre: 75mm Matériau du couteau: Plaque murale n ° 45 THK : Emballage de transport de 16 mm: Caisses en bois Origine: Chine Certification: CE, ISO Conception de vis: Double vis Application: Plaques, machines et matériel Grade automatique: Bobine automatique THK: 0,4 ~ 0,6 Station à rouleaux: 17 Puissance de l'hydraulique: 5,5kw Matériau de Rouleau: # 45 HRC: 58-60 Marque déposée: WILLING Spécifications: Machine de formage de rouleaux de carreaux d'acier CE et ISO \ nComposants pour la machine: \ nLa machine de formage à rouleaux comprend une unité de déroulage manuel, un guide d'alimentation, des stations de formage à position fixe, une matrice de pressage, un équipement de coupe, une station hydraulique, une console PLC et une table de déchargement manuel du produit. \ n \ n \ n

\ nComposants pour la machine: \ nLa machine de formage à rouleaux comprend une unité de déroulage manuel, un guide d'alimentation, des stations de formage à position fixe, une matrice de pressage, un équipement de coupe, une station hydraulique, une console PLC et une table de déchargement manuel du produit. \ n \ n \ n \ nDocuments d'expédition: \ n1) Connaissement, un jeu complet; 2) Facture commerciale, triplication, 3) Liste de colisage, triplication. \ N \ n Composant et fonction:

\ nDocuments d'expédition: \ n1) Connaissement, un jeu complet; 2) Facture commerciale, triplication, 3) Liste de colisage, triplication. \ N \ n Composant et fonction:

Emballage et expédition \ n \ n1.Un conteneur de 40 pieds pour charger une machine avec dérouleur manuel; 2.L'huile antirouille essuyée entière, contrôleur PLC recouvert d'un film de mousse; 3. pièces de rechange et quelques petites pièces emballées dans une boîte à outils en plastique; 4.Tous les composants fixés par fil d'acier avec Container.FAQ Q: Êtes-vous un fabricant? R: Oui absolument. Bienvenue beaucoup pour votre visite chez nous. Q: quel est le délai de livraison? A: Normalement prendra 60 jours Q: Avez-vous un support après-vente? R: Oui, nous sommes toujours là pour vous donner des conseils et une assistance pour les détails techniques puisque nous avons un technicien senior. Q: Y a-t-il un contrôle de qualité lors de la fabrication des lignes? R: Oui, nous avons un groupe d'équipe qui sera responsable du contrôle de la qualité de la mise à disposition de la matière première, du traitement des rouleaux et des autres pièces, du traitement de la surface et de l'arbre du rouleau, de l'assemblage, des tests et de l'emballage. Q: Quelle est votre force par rapport à l'autre fournisseur? R: Nous vous fournirons la meilleure qualité et le meilleur service. Nous vous donnerons de bons conseils au-delà de vos exigences. Les lignes sont faciles à installer et nécessitent peu de maintenance.

\ nComposants pour la machine: \ nLa machine de formage à rouleaux comprend une unité de déroulage manuel, un guide d'alimentation, des stations de formage à position fixe, une matrice de pressage, un équipement de coupe, une station hydraulique, une console PLC et une table de déchargement manuel du produit. \ n \ n \ n

\ nComposants pour la machine: \ nLa machine de formage à rouleaux comprend une unité de déroulage manuel, un guide d'alimentation, des stations de formage à position fixe, une matrice de pressage, un équipement de coupe, une station hydraulique, une console PLC et une table de déchargement manuel du produit. \ n \ n \ n \ nDocuments d'expédition: \ n1) Connaissement, un jeu complet; 2) Facture commerciale, triplication, 3) Liste de colisage, triplication. \ N \ n Composant et fonction:

\ nDocuments d'expédition: \ n1) Connaissement, un jeu complet; 2) Facture commerciale, triplication, 3) Liste de colisage, triplication. \ N \ n Composant et fonction:| Coil Feeding Equipment | Consists of one uncoiler with capacity of 5 tons and its base. The steel sheet is manually fed to the guiding equipment under the function of friction and traction. | ||||

| Infeed Guide | Adopting guiding bar and sliding block (sheet lubricator) to control the width and position of the steel sheet. The coil sheet is guided in the correct position and passed to the roll forming equipment. | ||||

| Mainframe Transmission | Transfer the main motor power to the rollers through chains and sprockets, and also transfer the coil sheet.ition and passed to the roll forming equipment. | ||||

| Roll Forming Stationt. | The main frame of machine is welded separately and the outside wall is connected by screw after being roto blasted on the surface. The rollers are surface-chrome plated after being machined by the exact machine tool. The tooling is PLC precision machined and supported with pre-lubricated rolling contact bearings. | ||||

| Post-cut Equipment | Stationary hydraulic post shear/guillotine. The length and quantity of pieces can be set by the buyer through the control console, when reach the set length, the machine will cut the panel automatically. The cutting is finished under the power of hydraulic station which guarantees the precision of cutting. | ||||

| Pressing Die System | To make pressing die for the steel sheet after roll formed, the shape of corrugated sheet will be pressed into steps. The distance of step length can be adjusted.e power of hydraulic station which guarantees the precision of cutting. | ||||

| Hydraulic Station | Supplies the initial power to the cuter through a closed oil tank. It is off without cutting, which can save the power.length can be adjusted.e power of hydraulic station which guarantees the precision of cutting. | ||||

| PLC Control Console | The electric controlling system of this machine consists of five parts: operating system, touch screen, PLC, transducer and strong electricity parts. The controlling system of this machine is imported from Siemens, Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be chosenoperation by manual or automatically.ystem, touch screen, PLC, transducer and strong electricity parts. The controlling system of this machine is imported from Siemens, Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be chosenoperation by manual or automatically.ystem, touch screen, PLC, transducer and strong electricity parts. The controlling system of this machine is imported from Siemens, Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be chosenoperation by manual or automatically.ystem, touch screen, PLC, transducer and strong electricity parts. The controlling system of this machine is imported from Siemens, Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be chosen operation by manual or automatically.gth 2 meters; it can support panels with more than 4 meters in normal condition.ens, Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be chosen operation by manual or automatically. | ||||

| Product Support Table | To support the finished run out panels. The quantity we supply is 2 pieces with length 2 meters; it can support panels with more than 4 meters in normal condition.ens, Germany. The system uses modularized structure and has convenient, reasonable, canonical wiring arrangement, and its maintenance is quite easy. The independent operating console facilitates the mutual dialogue between the operator and the machine. The operation is easy and steady and can be chosen | ||||

Groupes de Produits : Ligne de tôle ondulée / trapézoïdale

Premium Related Products

autres produits

Produits phares

Machine de formage de tuiles (WLFM28-207-828)Machine de décapage (WILLING)Machine de mur sec (WLFM-C80-U82)Rouleau formant la machine (WLFM18-76-988)C Machine de formage de lamelles (WLCM-1)Rouleau de support d'énergie solaire formant la machineMachine à coudre en acier CNCMachine de formage d'acier de couleur de la CNC de couche simple Undulator / rouleau de panneau de panneau de métalRouleau d'acier de couleur de la couleur de CNC de simple couche formant la machine / rouleau de panneau automatique de toit formant la machineLa nouvelle haute vitesse CNC Cut C Rouleau d'acier faisant la machine / la tôle de toiture de zinc faisant la machineLigne de production de mortier semi-automatiqueRouleau d'acier de couleur de la couleur de CNC de couche simple formant la machine / machine de presse d'acier / machine de tuile de toitHGC60-221-845B rouleau d'acier de couleur de la CNC de couche simple formant la machine / la formation de tuile de toitureRouleau de feuille de toiture galvanisé formant le rouleau / machines de forme de rouleau de tuile / tuile formant la machineColor Steel Composite Board Ligne de production / tôlerie métalliqueRouleau de purlin / Z